EFSA DECLARES HIGH-PRESSURE PROCESSING SAFE AS A WAY TO KILL PATHOGENS

A food processing technique that uses intense pressure for a specific length of time to kill microorganisms has been deemed safe by the European Food Safety Authority (EFSA).

In a scientific opinion that it has published, the EFSA said the approach, called high-pressure processing (HPP), did not raise greater concerns over food safety than other treatments.

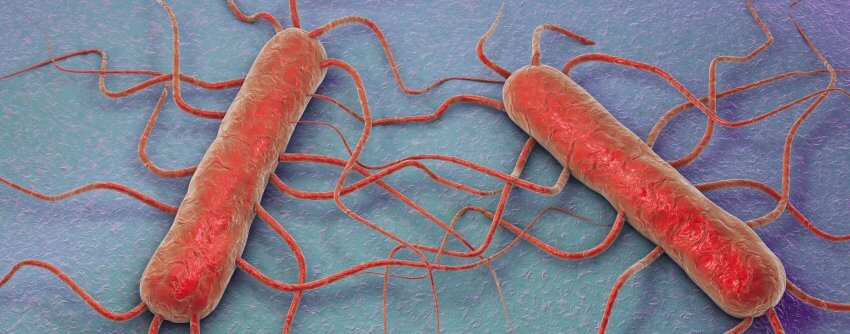

EFSA scientists looked particularly at whether HPP, which does not involve high temperatures, could be used to instead of thermal pasteurisation of raw milk, and to control a bacterium called Listeria monocytogenes in ready-to-eat foods.

According to the EFSA, the technique does little to change how food looks, how it tastes or its texture – and does not destroy nutrients.

“HPP can be used at different steps of the food chain, usually on pre-packed products,” the EFSA said in a statement.

“It can be applied to raw materials such as milk, fruit juices and smoothies, but also to products that have already been processed, such as sliced cooked meat products and ready-to-eat meals.”

When used on products that have already undergone processing, its main function is to kill pathogens that may have been introduced during the manufacturing process.

In the scientific opinion that it published, the EFSA said the longer HPP is used, the better the reduction in the levels of contaminants.

With raw milk, the time-pressure combination that has the same effects as thermal pasteurisation depends on the pathogen.

In related news, Sial Paris Newsroom recently reported that steam heated to 250 Fahrenheit – at which temperature it acts like a hot gas – can be used to clean food processing plants.

Join us at SIAL Paris as exhibitor Join us at SIAL Paris as visitor